Smart-textile design

Developing connected garments and smart textiles tailored to your use case and constraints.

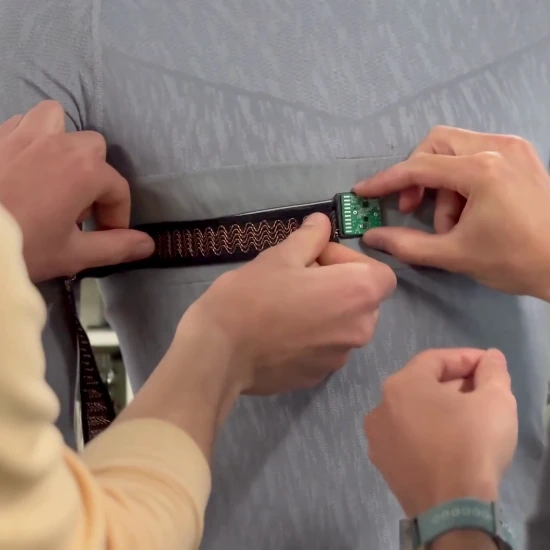

Developing your connected garment from A to Z

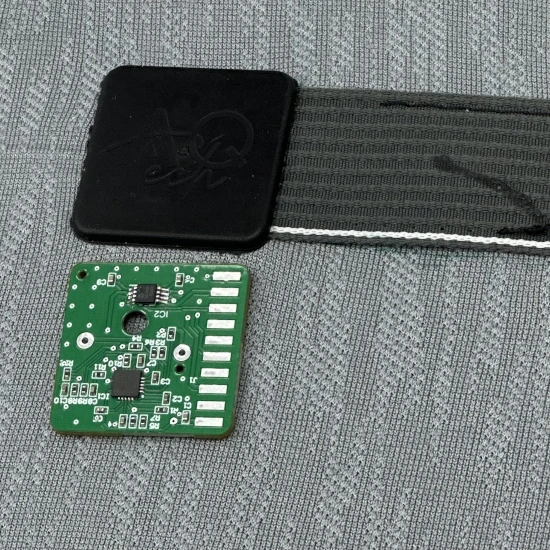

From product idea to full e-textile architecture: textile, sensors, conductive paths, connectors and electronic modules.

Co-design workshops

Dedicated sessions with your product, R&D and marketing teams to frame your connected garment.

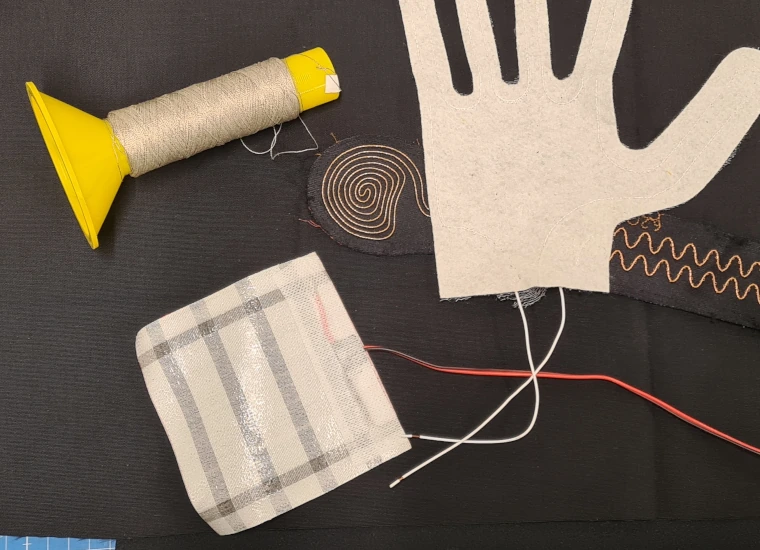

Technology exploration

Comparison of textile, sensor and connector technologies suitable for your use case.

Textile & e-textile lab

Textile prototypes, pathway architectures, sensor positioning and comfort testing.

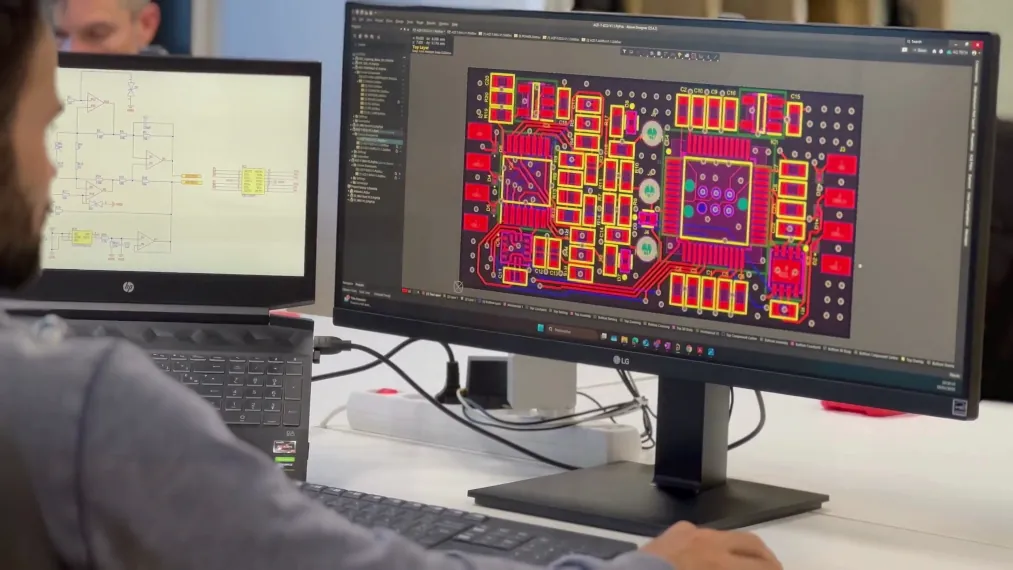

Electronics expertise

Specification of modules, interfaces, protocols and electrical constraints linked to textiles.

FAQ — Developing connected garments

Where should I start when developing a connected garment?

The first step is to clarify the use case, the signals to measure, comfort constraints and the real conditions of use. We help you define all these elements and build the right e-textile architecture.

Can you work from an existing garment?

Yes, we can adapt an existing pattern or product line to integrate sensors, conductive paths and electronic modules while preserving your product’s identity.

What is the difference between a smart textile and a connected garment?

A smart textile integrates active functions (sensing, actuation, conduction…), while a connected garment also includes electronics, communication and often a data platform or app.

Do you also support prototyping and industrialisation?

Yes, AQ-Tech can support the entire chain: design, integration, prototyping, pre-series and industrialisation with your textile and electronics partners.