How to Succeed in a Product Architecture Study

You have an innovative product idea, maybe even a detailed specification sheet. The next logical step seems to be prototyping. But before diving into design and industrialization, there’s a critical step that separates successful projects from failed ones: the product architecture study. This phase defines how your idea will come to life, balancing innovation, feasibility, and long-term efficiency.

1. What is a product architecture study?

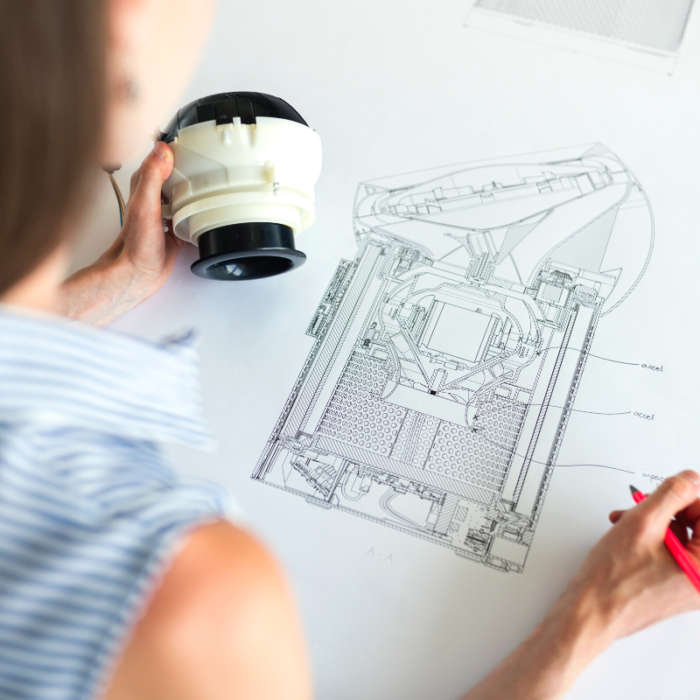

At AQ-Tech, the product architecture study — also called the feasibility or pre-study phase — is the foundation of every technical project. It aims to analyze functions, constraints, and interactions to build a coherent and optimized product architecture before any detailed design begins.

The goal is simple: identify and compare potential technical solutions for each function of the product. Which technologies are best suited? How will the parts be assembled? What are the trade-offs between cost, energy consumption, weight, or reliability?

For instance, if you plan to develop a connected sensor, the study will explore multiple communication technologies (Bluetooth, Wi-Fi, LTE-M, etc.), battery chemistries, and housing options. Each choice is evaluated based on measurable criteria — cost, autonomy, integration constraints — to minimize risk during the next stages.

2. The key steps of a product architecture study

a. Start with the requirements

The starting point is your product specification. Even when it’s detailed, AQ-Tech reformulates it into a technical matrix that clarifies expectations and reveals missing elements. We start by asking: what must the product do, under what conditions, and with what performance level?

Beyond normal operation, the study considers edge cases and lifecycle events:

- What happens when the battery runs low?

- How should the product behave if a sensor fails?

- Is firmware upgradable over time?

- What happens during recycling or end-of-life?

b. Identify all constraints

Every function exists within limits — mechanical, environmental, or market-related. The study examines them thoroughly:

- Does the product need to be waterproof, shock-resistant, or medical-grade?

- What surface finish or material durability is required?

- Which certifications or standards must be met?

- What cost and production volume targets are defined?

This step ensures the design team works with a complete understanding of trade-offs between function, performance, and manufacturability.

c. Analyze and compare solutions

Once the functions and constraints are defined, we move on to solution mapping. For each need, multiple technologies are evaluated — from connectivity modules and sensor families to materials and manufacturing processes (injection molding, machining, additive manufacturing). Each solution is rated on feasibility, cost, complexity, and long-term reliability.

By comparing options quantitatively, we eliminate weak solutions early and converge toward a validated product architecture that meets performance, cost, and production goals.

3. Success factors for a great architecture study

Success in this stage depends on two main factors:

- Comprehensive vision: covering every step of the product lifecycle — design, manufacturing, usage, maintenance, and recycling.

- Risk management: systematically derisking functions before prototyping saves significant time and money later.

The most common mistake is to start development with an incomplete or idealized specification. Ignoring aspects like manufacturing feasibility, logistics, or product robustness leads to costly redesigns later. A well-structured architecture study avoids this by clarifying decisions before they become problems.

Another crucial aspect is aligning the study depth with the project phase. Early prototypes can work with simplified assumptions, but final designs require detailed validation of every constraint and interaction.

4. Collaboration is the key

The architecture study is not a one-way process — it’s a dialogue. You bring your product vision and market expertise; AQ-Tech brings technical mastery and system-level thinking. Together, we co-develop an architecture that balances innovation, cost efficiency, and manufacturability.

Regular meetings, milestone reviews, and transparent documentation ensure alignment at every step. This collaborative dynamic is what turns a great idea into a successful product.

Remember: a well-executed architecture study is not wasted time — it’s time saved. It reduces uncertainty, accelerates design, and increases your chances of delivering a product that works the first time.

To learn more about AQ-Tech’s methodology, discover our services in innovation and prototyping, or get in touch with our engineers to discuss your upcoming project.