5 Key Principles to Succeed with Your Plastic Injection Mold

For every company bringing a physical product to market, the plastic injection mold is both a milestone and a challenge. It’s an essential step that determines the quality, durability, and cost efficiency of your production. Yet, due to its cost and complexity, it’s often one of the most critical decisions in product industrialization.

At AQ-Tech, we design and open new molds regularly, supporting clients from prototype to full-scale production. Here are five key practices we’ve refined to ensure every mold project leads to a successful, long-term industrial outcome.

1. Understand the plastic injection process

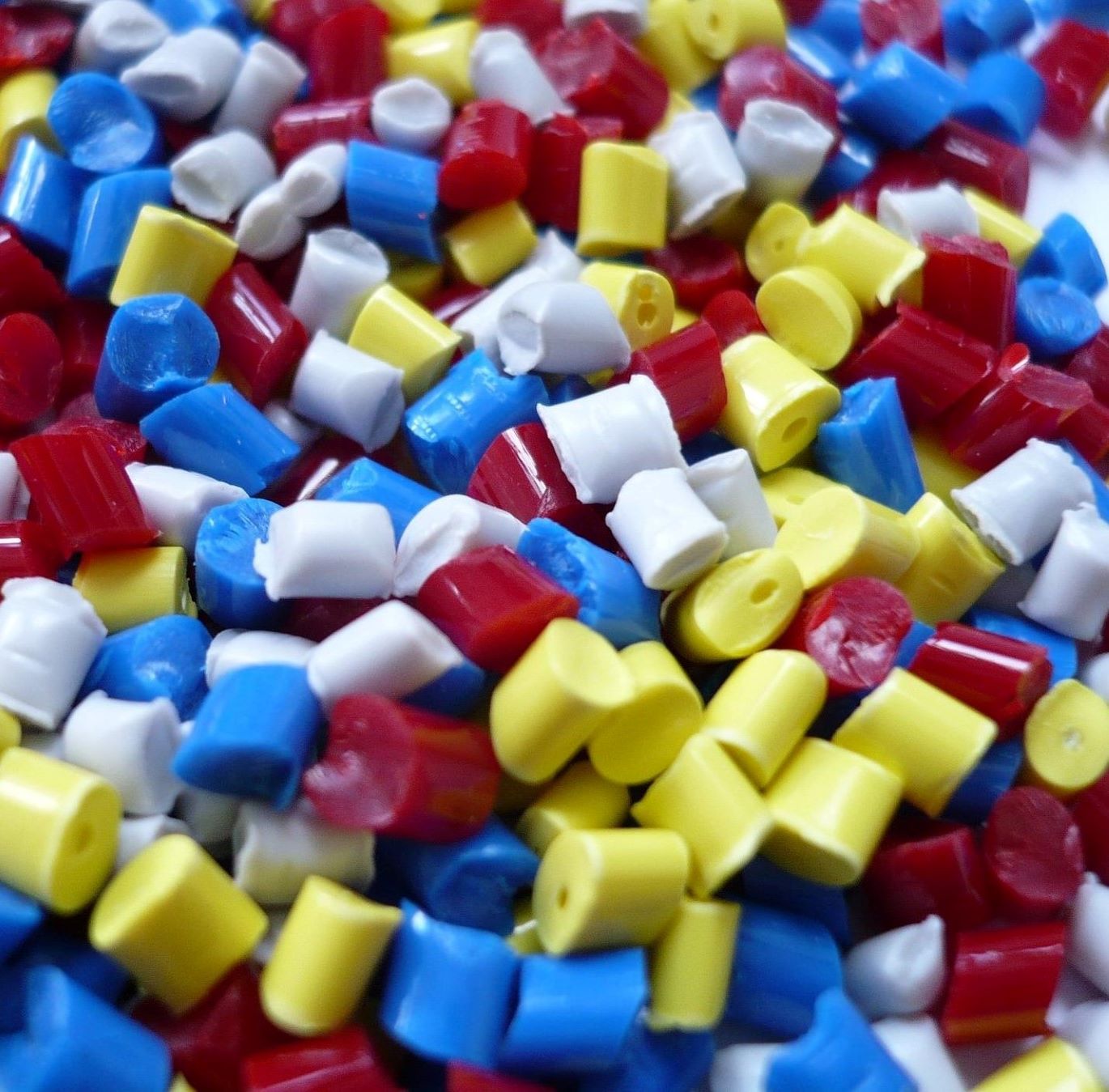

Plastic injection molding involves melting thermoplastic granules and injecting them into a steel mold under high pressure. Once cooled, the mold opens, and the part is ejected. The result: precise, repeatable, and cost-efficient production for high volumes.

Each production setup relies on three essential components:

- Thermoplastic material: ABS, PA, PC, POM, or even recycled plastics, chosen based on mechanical, aesthetic, or environmental needs.

- The mold itself: a custom steel or aluminum tool designed specifically for your part geometry.

- The injection press: an industrial machine that forces molten material into the mold cavity at controlled pressure and temperature.

Understanding this process is the foundation for all design and decision-making. A good mold design ensures production speed, dimensional accuracy, and part durability over hundreds of thousands of cycles.

2. Don’t rush the tooling phase

Tooling is a major investment. A single mold can cost tens of thousands of euros and take months to produce. Any design change afterward can be extremely costly. That’s why it’s essential to validate the part and material before machining the mold.

Step 1: Make material-accurate prototypes

Every polymer behaves differently. Shrinkage rates, stiffness, and elasticity all vary. Machining prototypes from the actual plastic material (rather than 3D-printed substitutes) allows you to verify mechanical behavior and assembly fit before final tooling.

Step 2: Conduct pre-series runs

Before committing to full-scale production, test a limited batch. Techniques such as vacuum casting, CNC machining, or aluminum prototype molds allow near-injection results without full investment. This stage helps uncover assembly, tolerance, or flow issues that CAD models can’t predict.

Learn more about AQ-Tech’s industrialization services to secure your tooling process and reduce risks before mass production.

3. Anticipate constraints during design

Injection molding comes with its own geometry rules. Parts must respect draft angles for demolding, uniform wall thickness to prevent sink marks, and no undercuts unless mechanically managed. Designs optimized for 3D printing rarely translate directly to injection without modification.

At AQ-Tech, our engineers integrate injection constraints from the very first sketches. Every part is designed with manufacturability in mind. We analyze gate placement, flow direction, joint lines, and cooling channels to ensure the mold can be built efficiently and reliably.

This anticipatory design approach may add a few hours during CAD work, but it saves weeks during mold validation and debugging.

4. Choose the right partners

Injection molding projects typically involve two key players: the toolmaker (mold maker) and the molder (injection partner). They must collaborate closely, especially when deadlines and precision are tight.

Our preferred approach is to work with hybrid partners — companies that handle both tooling and molding. This ensures seamless communication, faster troubleshooting, and consistent quality. However, for complex or high-volume molds, working with specialized partners for each phase may be more efficient.

5. Fine-tuning and quality management

Once the mold is complete, the first series of parts will rarely be perfect. This stage is known as fine-tuning (MAP – Mise Au Point). Dimensions must be adjusted, surfaces refined, and injection parameters optimized. The goal is to reach perfect conformity before serial production begins.

At AQ-Tech, we anticipate critical adjustment zones in advance and define a clear correction strategy. This proactive planning prevents costly rework and extends the mold’s lifetime. Surface treatments — texturing, polishing, or engraving — are also planned early to align with design and manufacturing goals.

6. Documentation and long-term reliability

Once validated, your mold becomes a long-term asset. To maintain consistent quality over time, it’s essential to document and update:

- 2D and 3D CAD files: reflecting every modification made during fine-tuning.

- Injection parameters: temperature, pressure, cycle time, and cooling data from the production press.

- Quality control protocol: frequency of inspection, critical dimensions, and acceptable tolerances.

This documentation ensures repeatability and protects your investment from quality drift over time.

With the right partners and a rigorous process, your injection mold becomes a cornerstone of your product’s industrial success. Need expert guidance for your project? Contact our engineering team — AQ-Tech helps turn complex designs into manufacturable, reliable products.