AQ-Tech Engineering: Design, Prototyping, Industrialisation & Assembly

Complete engineering services to develop your mechanical, electronic, textile and mechatronic products.

The benefits of our engineering services

With full control of the product development cycle, AQ-Tech reduces risks, accelerates technical iterations and ensures a reliable industrialisation with no functional gaps between disciplines.

Process mastery

A structured process from concept to pre-series: framing, system architecture, technical validations and controlled documentation.

Agility & responsiveness

Short cycles, rapid technical decisions, iterative prototypes and continuous adaptation based on the project’s real progress.

Partner ecosystem

Direct access to a proven industrial network: manufacturers, laboratories, materials experts and specialised processes.

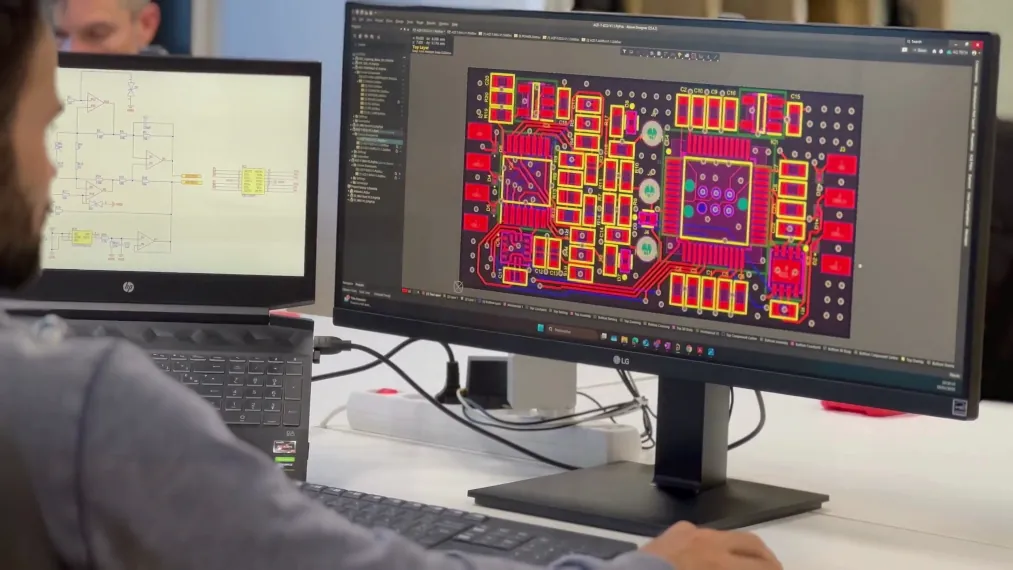

Iterations & validation

Fast prototyping, mechanical/electronic/textile testing, EMC verification, real-usage evaluation and structured convergence.

Complete engineering services

AQ-Tech supports every step of the product development cycle: design, prototyping, industrialisation and assembly. A fully integrated process ensuring reliability, performance and an optimised time-to-market.

FAQ – AQ-Tech Engineering Services

What parts of a project can you handle?

We cover the full cycle: mechanical/electronic/textile design, prototyping, testing, industrialisation and assembly. You may entrust us with a specific phase or the entire product development.

Can you deliver a production-ready product?

Yes. We manage system architecture, prototypes, tests, documentation and pre-series. We deliver a functional, reliable, industrialisable product.

How do you collaborate with in-house teams?

We can co-develop, take responsibility for a subsystem or manage the full project. Our involvement adapts to your internal skills and R&D organisation.

Do you accept complex or poorly-defined projects?

Yes. Our multidisciplinary approach helps structure the architecture quickly, identify early risks and launch technical iterations even with an initially vague need.

How do you manage technical risks?

Every decision is validated by a prototype or test: mechanical analysis, electronics tests, EMC checks, usage validation and risk assessments. This iterative approach secures the design before pre-series.

What are the typical project timelines?

Design: 8–12 weeks. Prototyping: 4–8 weeks. Pre-series: 3–6 months. Timelines vary depending on mechanical/electronic complexity and functional requirements.

Can you handle manufacturing or assembly?

Yes. We assemble small series in-house, perform final tests and prepare the industrial transfer for volume production. We deliver full assembly and quality-control documentation.

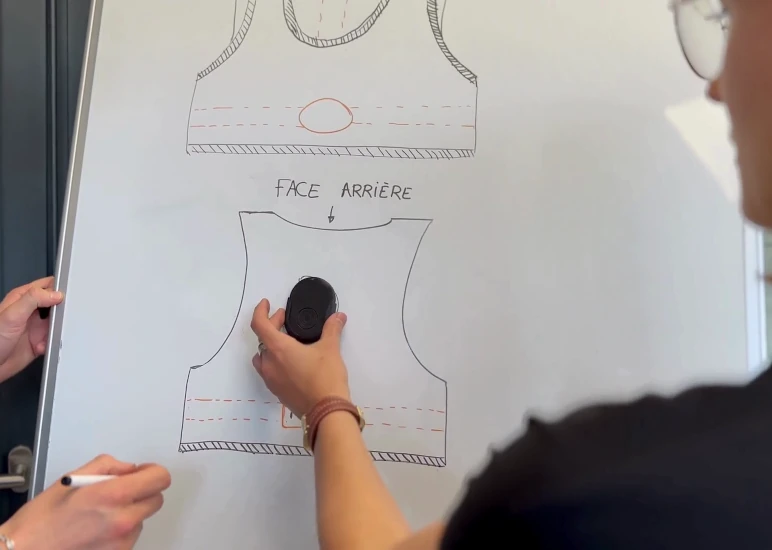

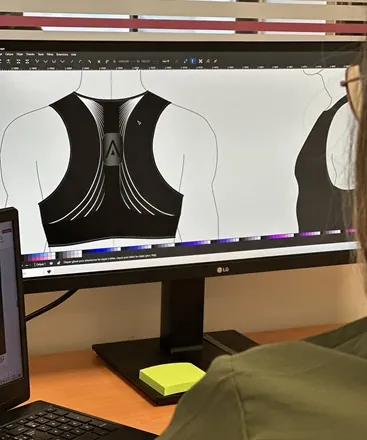

Do you work on textile or smart-textile projects?

Yes. We integrate technical textiles, soft structures, sensors, ECG/IMU/pressure systems, overmoulding and embedded firmware. This unique expertise allows us to develop industrialisable technical or smart-textile products.