Multidisciplinary Engineering: Mechanical, Electronic and Technical Textile

AQ-Tech develops your industrial, mechatronic and technical textile products from concept to production.

The benefits of a multidisciplinary approach

A coherent integration of mechanics, electronics and textiles leads to more reliable products, more compact architectures, easier industrialisation and faster time-to-market.

Mechanical Design

Enclosures, mechanisms, kinematics, assemblies, materials, prototypes and mechanical testing.

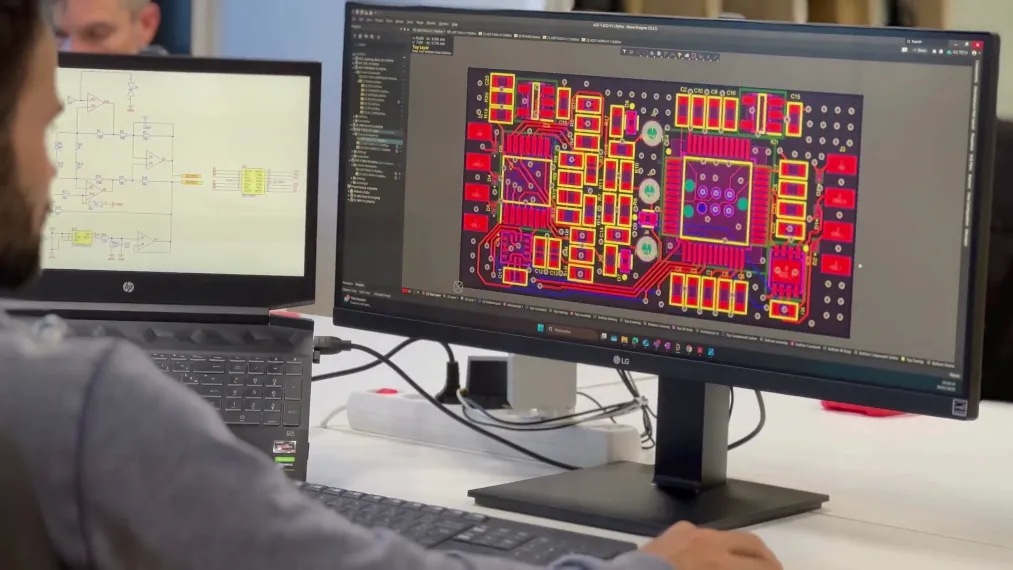

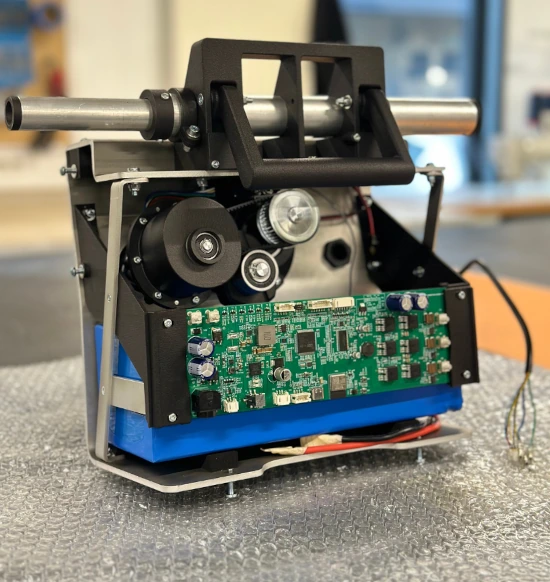

Electronics & Firmware

Electronic boards, sensors, power management, communication, embedded firmware.

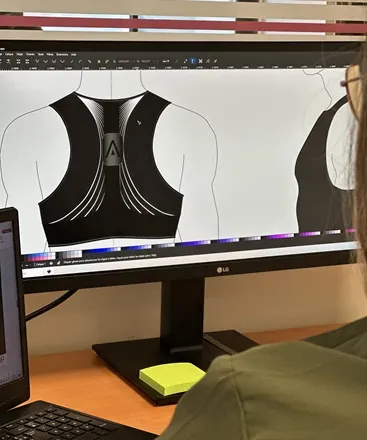

Technical Textiles

Materials, soft structures, reinforcements, ergonomics, integration into mechanical systems.

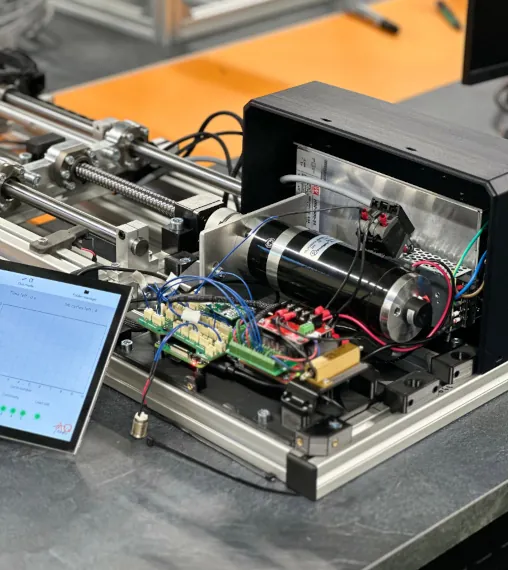

Prototyping & Industrialisation

Processes, assembly, documentation, validation, pre-series, quality control.

Integrated Technologies & Skills

AQ-Tech brings together mechanics, electronics, embedded software, technical textiles and mechatronic machine design in a single team. This integration enables complete, coherent and industrial-grade products.

Multidisciplinary Engineering – FAQ

Which disciplines do you integrate in-house?

Mechanics, electronics, firmware, technical textiles, automation and prototyping. This integration eliminates workflow gaps and accelerates product development.

Can you develop a complete product?

Yes. We handle system architecture, design, prototyping, testing, industrialisation and documentation. The objective: a reliable, functional, manufacturing-ready product.

Do you work with internal client teams?

We can co-develop with your staff, take charge of a subsystem or lead the full project. Our involvement adapts to your structure and internal skillset.

Do you take on complex or poorly defined projects?

Yes. We specialise in projects combining mechanics, electronics, textiles and embedded software. We structure the architecture and identify risks early in the process.

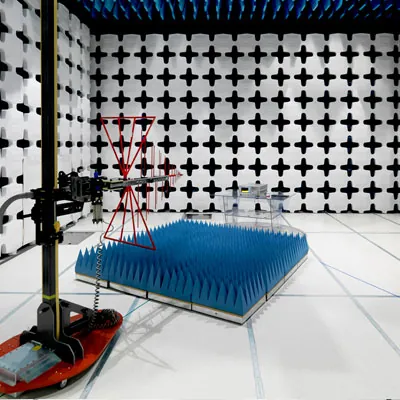

How do you ensure the reliability of your developments?

Mechanical, electrical and functional tests, EMC trials, risk analysis and rapid prototype iterations. Systems are validated under realistic usage conditions.

What are the typical development timelines?

Studies: 6-8 weeks, prototyping: 8–16 weeks, pre-series: 3–6 months. Timelines depend on mechanical–electronic complexity and required performance.

Do you develop embedded firmware?

Yes. Low-level firmware, sensor drivers, energy optimisation, real-time synchronisation and communication protocols for advanced embedded systems.

Can you design mechatronic machines?

Yes. We design mechanical structures, electronics, actuator control and embedded firmware. We deliver ready-to-use machines, test benches and mechatronic modules.