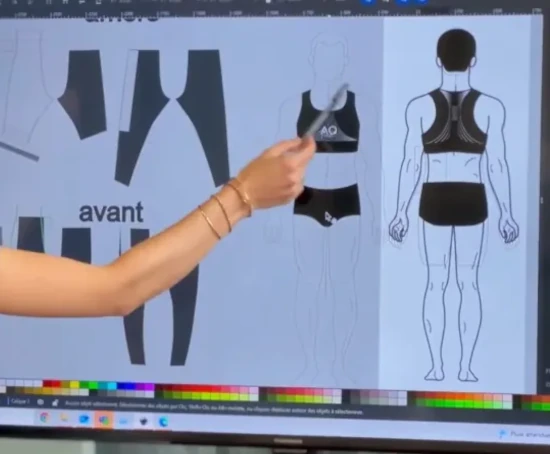

Smart Textile Industrialization: methods, robustness and repeatability

Turning a connected textile into a scalable, durable, controlled and use-stable product.

Our Smart Textile industrialization services

Specialized e-textile industrialization: processes, tooling, controls and long-term validation.

E-textile specialization

Industrialization designed for wearable, washable and fatigue-prone products.

Controlled processes

Tooling, in-process controls and repeatable methods.

Long-term validation

Robustness and signal stability in real-use conditions.

Workshop transfer

Industrial files usable by textile production lines.

FAQ — Smart Textile Industrialization

When should Smart Textile industrialization start?

As soon as the prototype is functional and you need to secure repeatability, durability and workshop methods. In smart textile projects, waiting until “the end” to industrialize is a mistake: material, assembly and encapsulation choices must be designed for production from the first prototyping iterations.

How is it different from conventional electronics industrialization?

Textiles introduce phenomena that do not exist in electronics: permanent deformation, material dispersion, gesture variability, and use constraints (washing, abrasion, bending). A viable process must control these variations while maintaining stable electrical performance.

How do you ensure washability of a connected textile?

Washability depends on the full architecture: materials, stress zones, encapsulation, connector interfaces and process compatibility. AQ-Tech runs representative wash cycles and combined electrical/mechanical checks to identify failure mechanisms and adjust the product before series.

What are typical risks in Smart Textile production?

The most common are batch-to-batch quality drift, intermittent failures, delamination, sensor placement variation, and signal instability driven by fatigue or humidity. These issues can be prevented with in-process controls and workshop-ready industrial files.

Can you work with our textile workshop or subcontractors?

Yes. AQ-Tech prepares the industrial transfer and supports your partners (textile, electronics, assembly) during the first runs: operating procedures, tooling, controls, acceptance criteria and smart textile know-how ramp-up.

Do you provide Smart Textile assembly?

Yes, both for pre-series (to stabilize the process, validate quality controls, measure production dispersion and lock critical points before scaling) and for actual production runs. Our assembly workshop is equipped to manage this type of complex manufacturing.

Can you prepare elements for future compliance (CE / medical)?

Yes. For smart textile projects under regulatory requirements, AQ-Tech structures documentation, validations and technical elements (processes, controls, traceability, robustness) to support the compliance phase driven by your product strategy.

What documentation is required to produce a smart textile in series?

Hybrid documentation: coherent textile and electronics BOMs, patterns and integration drawings, operating procedures, control instructions, acceptance criteria and assembly/encapsulation rules. The goal is that a workshop can produce without relying on undocumented “tribal knowledge”.