Smart Textile Prototyping & Validation

Validate design and performance before moving to production.

Our Smart Textile Prototyping Services

From first concept to functional testing — complete prototyping for your connected textiles.

Smart Textile Laboratory

Sewing, laminating, overmolding, multi-material integration.

Prototype Workshop

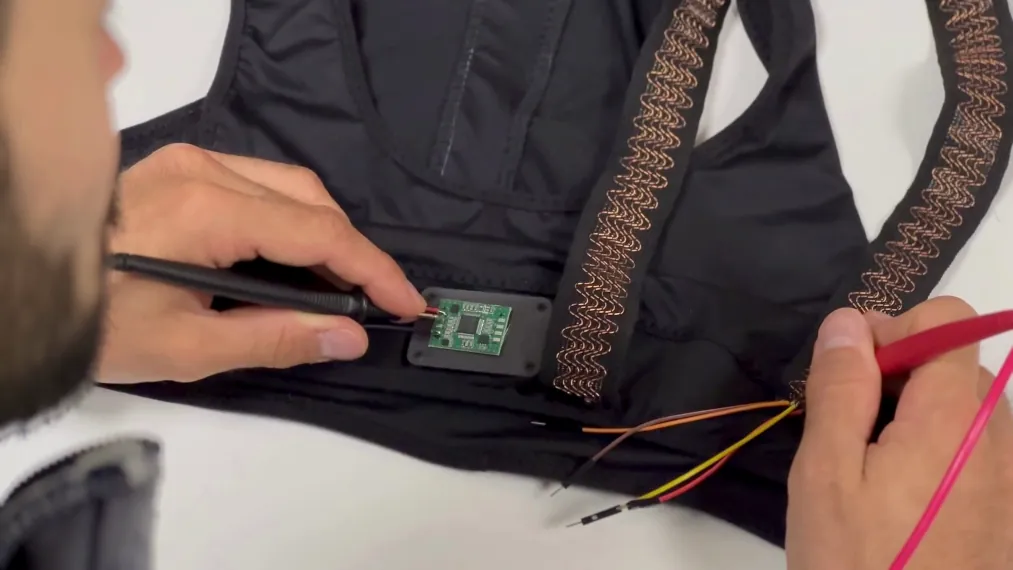

Creation of instrumented prototypes with sensors and actuators.

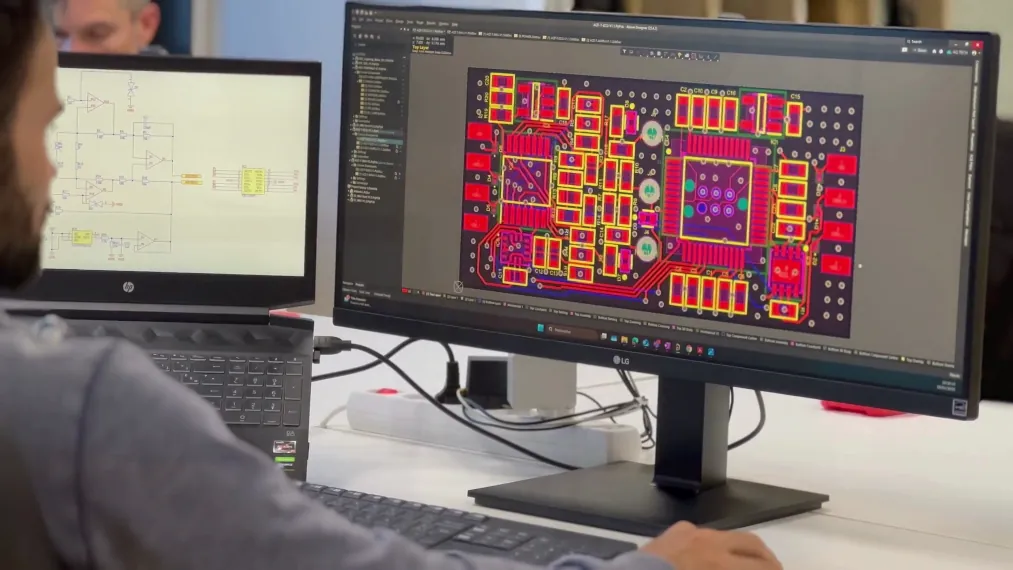

Embedded Electronics

Assembly, low-power drivers, firmware, data acquisition.

Testing & Validation

Signal, comfort, real-life use, endurance, washing, mechanical reliability.

FAQ — Smart Textile Prototyping & Wearable Devices

What is the purpose of Smart Textile prototyping?

Prototyping validates textile architecture, sensor integration and associated electronics before more complex and costly industrialization steps.

Do you create wearable, testable prototypes?

Yes, we develop real garments or accessories with integrated electronics, ready for field testing (comfort, measurement, washing, robustness, real-life use).

How many iterations are typically required?

Depending on complexity, 2 to 4 prototyping loops are usually needed to converge on a version validated both technically and ergonomically.

Can you support industrialization afterwards?

Yes. Once the prototype is validated, we prepare the pre-series (process, technical files, tooling) and support full-scale production with your partners or ours.