Smart Textile: Design, Prototyping & Industrialization of Intelligent Textiles

AQ-Tech develops your smart textiles and connected garments, from concept to production.

The benefits of smart textiles

Smart textiles transform a garment or equipment into a measurement, analysis and interaction platform. They enhance user performance, simplify usage, and provide real-time physiological or mechanical data.

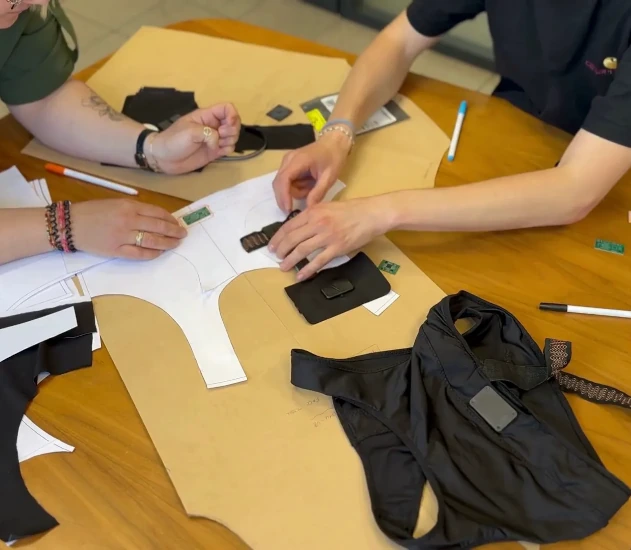

Smart Textile Architecture

E-textile architecture, conductive tracks, electrodes, modules, connectors.

Textile Sensors

ECG, EMG, IMU, pressure, respiration, temperature, biomechanics.

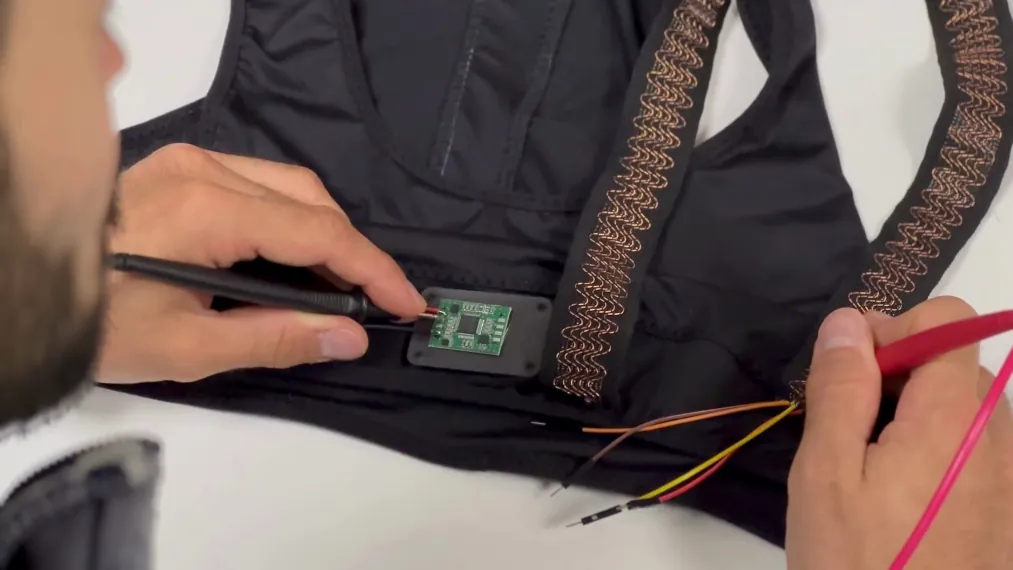

Mechanical–Electronic Integration

Overmolding, encapsulation, textile connectors, flexible modules.

Industrialization

Reproducible textile processes, washing durability, CE/MDR preparation.

Technologies integrated into smart textiles

Smart textiles combine sensors, actuators, conductive tracks and miniaturized electronics to transform a textile into a system that can measure, interact and act. These technologies enable reliable, comfortable, washable and industrializable products.

Smart Textile – FAQ

What types of sensors can be integrated into a smart textile?

We integrate a wide range of sensors: ECG, EMG, 6/9-axis IMU, pressure sensors, respiration (RIP), temperature, resistive/capacitive sensors or fully custom biomechanical systems. Each architecture is adapted to the intended use and required reliability.

How do you ensure the reliability and washability of a Smart Textile?

Reliability is achieved through robust protection methods: silicone overmolding, encapsulation, multilayer laminating, reinforced textile connectors and material selection compatible with washing. All products undergo mechanical tests, repeated washing campaigns, electrical measurements and endurance testing.

Can you produce Smart Textile prototypes?

Yes. AQ-Tech develops fully functional prototypes: textile, sensors, embedded electronics, firmware, overmolding, connectors and test benches. These prototypes validate signal quality, ergonomics, durability and integration.

Can you support industrialization of a smart textile?

Yes. We define reproducible processes: textile-electronics manufacturing methods, material selection, quality control protocols, industrial documentation and bill of materials. We collaborate with certified partners and prepare all required production documents.

Do you work on medical Smart Textile projects?

Absolutely. We support the development of medical textile devices integrating physiological sensors (ECG, EMG, respiration, temperature). We also prepare the key elements for future CE / MDR certification: technical architecture, risk analysis, preliminary testing and industrial dossiers.

Can a smart textile remain comfortable and discreet?

Yes. We develop discreet, flexible and lightweight architectures: textile electrodes, flexible tracks, miniaturized modules, flat connectors and thin encapsulation. The goal is to create smart textiles that remain comfortable, breathable and unobtrusive.

What are the typical lead times for developing a Smart Textile?

Timelines vary depending on textile complexity, sensors and firmware. Typically: – 2–6 weeks for the architecture & study phase – 4–12 weeks for functional prototyping – 3–6 months for pre-series & industrial preparation. We adapt timelines according to maturity and requirements.

Can you integrate our own sensors or electronics?

Yes. We can use your existing electronics or develop a custom PCB. We adapt the textile and mechanical interfaces to ensure compatibility, washability, robustness and signal integrity.