Technical Textile Expertise

Flexible materials serving performance and innovation

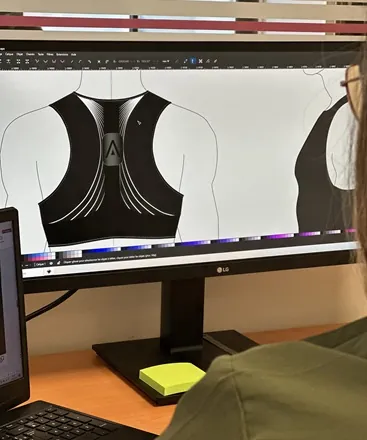

Our technical textile know-how

We transform textile materials into flexible, robust, and industrializable solutions, combining innovation, functionality, and performance.

Cutting & Assembly

Laser cutting, HF welding, technical sewing, and heat-sealing.

Technical Materials

Coated fabrics, composites, membranes, conductive textiles.

Textile Prototyping

Assembly, mechanical testing, sealing, and resistance tests.

Series Preparation

Industrial documentation, BOMs, drawings, and production transfer.

Frequently Asked Questions About Technical Textiles

What types of textiles do you work with?

We work with a wide range of technical fabrics: polyester, aramid, TPU, PVC, silicone, conductive, or composite materials — chosen according to the project’s mechanical and environmental constraints.

Do you manufacture textile prototypes?

Yes, our workshops produce textile prototypes and pre-series using sewing, HF welding, and laser cutting — allowing performance and ergonomics to be validated before industrialization.

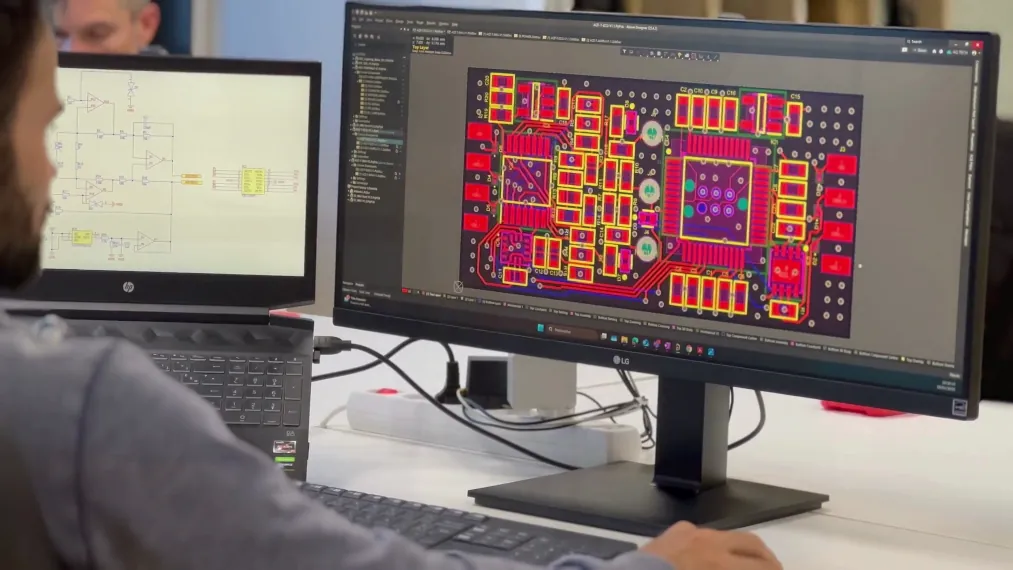

Can you integrate electronics into textiles?

Absolutely. We master textile-electronics integration through our Smart Textile division, combining flexible materials and embedded components.

Do you provide custom inflatable structures?

Yes, our expertise in inflatable textiles enables us to design flexible, airtight, and durable structures adapted to various applications.

Do you support production stages?

Yes, we produce internal pre-series and then transfer production to our qualified textile manufacturing partners in France or abroad.