The Major Challenge of Smart Textiles: Designing and Developing a Complete Product

Creating a smart textile product is one of the most complex challenges in modern engineering. It requires combining textile comfort with electronic functionality, mechanical robustness, and embedded intelligence — all within a flexible, washable, and user-friendly product.

At AQ-Tech, we believe that success lies in a 360° vision of the process — understanding every stage from material selection to data transmission. Let’s explore the essential steps to develop an industrial-grade smart textile solution.

1. Building a complete vision

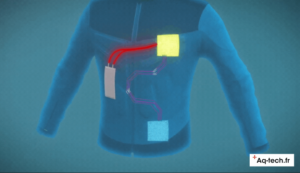

The foundation of every successful project is a global view of the system. Smart textiles are multidisciplinary by nature: they combine conductive materials, sensors, mechanical housings, electronic boards, and software logic. Each decision affects the others.

Goal: align all technologies and design choices toward a single outcome — a product that performs reliably, feels natural to wear, and can be manufactured at scale.

2. Choosing the right technologies

a) Integrating connectivity into fabric

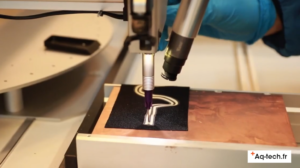

Connecting electronics within a textile requires selecting the right conductive pathway. Options include embroidered threads, woven conductors, and printed conductive inks. Each method offers a balance between flexibility, durability, and circuit complexity.

- Embroidery: simple and adaptable but limited in geometry; adds thickness to the garment.

- Weaving: highly integrated and durable but constrained by the fabric’s structure.

- Printed conductive inks: ideal for complex circuits and scalable production, though elasticity and washing durability must be managed.

Most advanced products rely on hybrid architectures, combining textile and electronic layers for optimal performance.

b) Sensor integration

Sensors transform a textile into an intelligent interface. They can measure physiological signals (ECG, EMG, respiration), body temperature, or environmental parameters like humidity and motion.

Choosing the right sensors means balancing accuracy, comfort, and integration constraints. Electrodes must maintain stable contact with the skin while remaining soft, stretchable, and washable. AQ-Tech specializes in designing textile electrodes and flexible connectors adapted to industrial manufacturing.

c) Actuation features

When a smart textile also acts — not just senses — the challenge multiplies. Actuators bring motion, heat, vibration, or light to the fabric. Heating elements and haptic feedback layers, for instance, must deliver performance without compromising safety, weight, or comfort.

d) Hardware junction and electronics integration

All data collected by sensors must be processed somewhere. The hardware junction — a compact electronic hub — centralizes power, communication, and processing. Its design requires close collaboration between mechanical, electronic, and textile engineers to ensure stability, ergonomics, and seamless integration.

PCB design, cable routing, and overmolding techniques must account for fabric elasticity and washing cycles. AQ-Tech’s multidisciplinary teams develop these solutions internally to ensure reliability under real-life conditions.

e) Wireless communication and data visualization

Once processed, data must be transmitted securely via Bluetooth, Wi-Fi, or LTE-M to a cloud platform or local device. The final interface — mobile app or web dashboard — allows users to visualize, analyze, or act upon the data collected by their smart textile.

3. Designing a fully industrializable product

Most prototypes fail not because the technology doesn’t work, but because it can’t be manufactured consistently. A true smart textile solution must be repeatable, maintainable, and certifiable. This requires understanding both textile manufacturing and electronic assembly constraints.

Unlike many design offices focused on a single domain, AQ-Tech integrates all competencies — mechanics, electronics, software, and textiles — to deliver turnkey smart textile systems. This integrated approach ensures that every part of the product works in harmony from prototype to industrial series.

4. AQ-Tech’s expertise

Our strengths:

- Cross-disciplinary expertise across textiles, electronics, mechanics, and embedded systems.

- Internal prototyping facilities for rapid design validation and iteration.

- End-to-end project management — from concept to pre-series and production.

Ready to develop your next-generation wearable? Contact our experts — AQ-Tech will help you turn your vision into a connected, reliable, and manufacturable product.