4 Key Steps to Successfully Prototype Your Idea

From concept to creation: bringing innovation to life

You believe in your idea. To make it real, rapid prototyping is the key. Whether it’s a mock-up, demonstrator, or functional prototype, each project requires a tailored approach. Here are the 4 essential steps to transform your idea into a tangible product.

1. Define your prototype’s objective

Every prototype must serve a clear purpose. Ask yourself: why do we need this prototype, and what do we want to validate? Each stage of development calls for a specific type of prototype — from aesthetic to functional.

- At the start, a simple 3D-printed model can validate design or feasibility.

- Later, a functional prototype helps confirm mechanical strength or comfort.

Knowing your goal helps define the right prototype and a relevant specification sheet.

+ AQ-TIPS

At AQ-Tech, we always set SMART objectives:

- Specific: clearly defined

- Measurable: quantifiable

- Achievable: accepted by the team

- Realistic: attainable within limits

- Time-bound: with a clear deadline

2. Write a clear specification sheet

Once your objective is clear, formalize it. The specification document helps your partner design a prototype that meets expectations while keeping creative flexibility.

Define key constraints (weight, dimensions, finish), but let your partner propose the most suitable materials and technologies. Overly rigid specifications limit innovation.

Our team can support you in this step — learn more about our methodology.

3. Design and bring your ideas to life

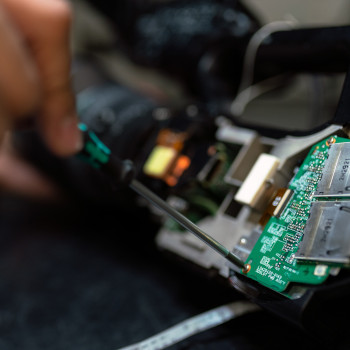

With the specifications ready, it’s time to create! From 3D modeling to electronic integration, every detail matters. The goal: a functional, reliable, and optimized prototype based on our expertise in mechanical design, electronics, and technical textiles.

+ AQ-TIPS

Our motto: iteration. Build fast, test, improve, and repeat. Iterative prototyping is the smartest way to achieve a design that meets all requirements — whether mechanical, electronic, or aesthetic.

3.1 Focus: 3D Printing

3D printing has transformed prototyping. Several technologies exist:

- FDM: fast and affordable, but rough finish.

- SLA: smooth, high-quality surface comparable to injection molding.

- SLS / MJF: precise and durable functional parts.

Depending on your needs, parts can be sanded, painted, or coated for a near-final appearance.

4. Test, learn, and iterate

Testing your prototype is crucial. The first versions are never perfect — and that’s the point! Testing helps validate assumptions, confirm design choices, and identify improvements.

+ AQ-TIPS

After each iteration, list all improvements and update your specifications to keep track of your progress.

Conclusion

Rapid prototyping is a decisive step in product development. Well-structured, agile, and iterative, it accelerates market readiness and minimizes risk. Remember: a prototype isn’t a final product, but a powerful learning and innovation tool.

Want to discuss your project? Learn more about our engineering company or contact us today.